Enhance Your Devices with Custom Membrane Switch for Optimal Results

Enhance Your Devices with Custom Membrane Switch for Optimal Results

Blog Article

Discover the Versatile Use Membrane Layer Switch Over in Modern Electronic Devices

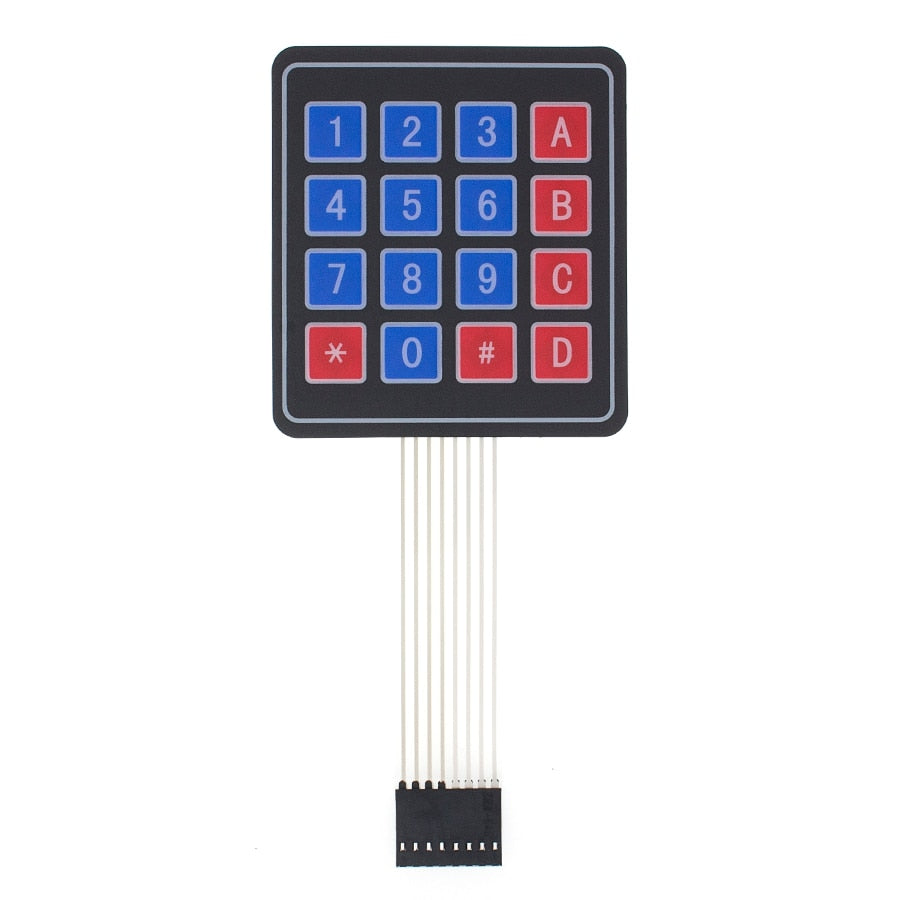

In the world of contemporary electronics, the application of membrane layer switches is extremely extensive, covering from sleek customer gadgets to vital clinical tools. These thin, flexible interfaces not only simplify tool procedure with their responsive responsiveness however additionally dramatically improve longevity by resisting ecological hazards like wetness and dirt. As markets continue to develop, the integration of membrane buttons in devices style is essential, encouraging not just to satisfy but exceed the strenuous needs of both capability and aesthetic appeal. Discover more regarding just how these components are forming the future of innovation.

Exploring the Role of Membrane Layer Switches in Customer Electronics

Why are membrane layer switches over so widespread in customer electronic devices? The solution exists in their distinct mix of versatility, reliability, and price. Membrane buttons are economical to make, making them an eye-catching choice for high-volume production regular in consumer electronics. Their construction, featuring a slim, adaptable layer that can quickly be incorporated into various devices, permits smooth, portable item layouts.

Moreover, these buttons are known for their resilience and low maintenance. From microwave ovens to remote controls, membrane switches give a functional, easy to use interface that sustains the dynamic nature of consumer electronics.

Membrane Changes in Medical Instruments: Enhancing User User Interfaces

Membrane switches also play a considerable duty in the realm of medical tools, where they boost customer interfaces with their distinctive benefits. The smooth, sealed surface of membrane switches allows for easy disinfection, decreasing the threat of contamination and spread of virus.

Membrane buttons likewise contribute to the durability of clinical tools. Their resistance to contaminants and fluids guarantees that essential tools remains operational in numerous professional setups, consisting of surgeries where direct exposure to liquids is usual. This resilience, paired with responsive responses and important source low-profile design, makes membrane changes an integral component you can check here in improving the efficiency and safety of medical tool interfaces.

The Influence of Membrane Layer Turns On Industrial Devices Style

In the world of commercial devices style, the unification of membrane switches has noted a significant evolution. The slim account of membrane changes enables for even more small device layouts, while their resistance to chemical, water, and dust impurities makes them ideal for industrial setups.

Additionally, the customizability of membrane layer changes allows developers to integrate particular tactile feedback and visual overlays that enhance the user experience and rise effectiveness. This assimilation sustains drivers in attaining accuracy control over intricate machinery. The general impact is a substantial enhancement in the functionality, reliability, and user-friendliness of commercial tools, lining up with the enhancing needs for technical innovation and operational effectiveness in contemporary sectors.

Verdict

Membrane buttons have transformed contemporary electronics, supplying sleek, sturdy, and customizable user interfaces across various sectors. Membrane Switch. In consumer electronic devices, they enhance the aesthetic and performance of tools. Clinical industries benefit from their trustworthy, user-friendly controls, critical for sensitive environments. Commercial applications value their resilience and performance. This modern technology not just why not try this out satisfies the demanding problems of different areas however additionally substantially enhances individual experience, making membrane layer switches over a foundation of modern electronic style.

In the realm of modern electronics, the application of membrane layer switches is incredibly extensive, extending from sleek consumer devices to critical medical gadgets.Why are membrane changes so common in customer electronics? Membrane layer buttons are cost-effective to produce, making them an attractive alternative for high-volume production typical in customer electronic devices. From microwave stoves to remote controls, membrane layer buttons supply a functional, user-friendly interface that supports the vibrant nature of consumer electronics.

Report this page